Transformation revving up production

China Daily2025-07-05 11:11

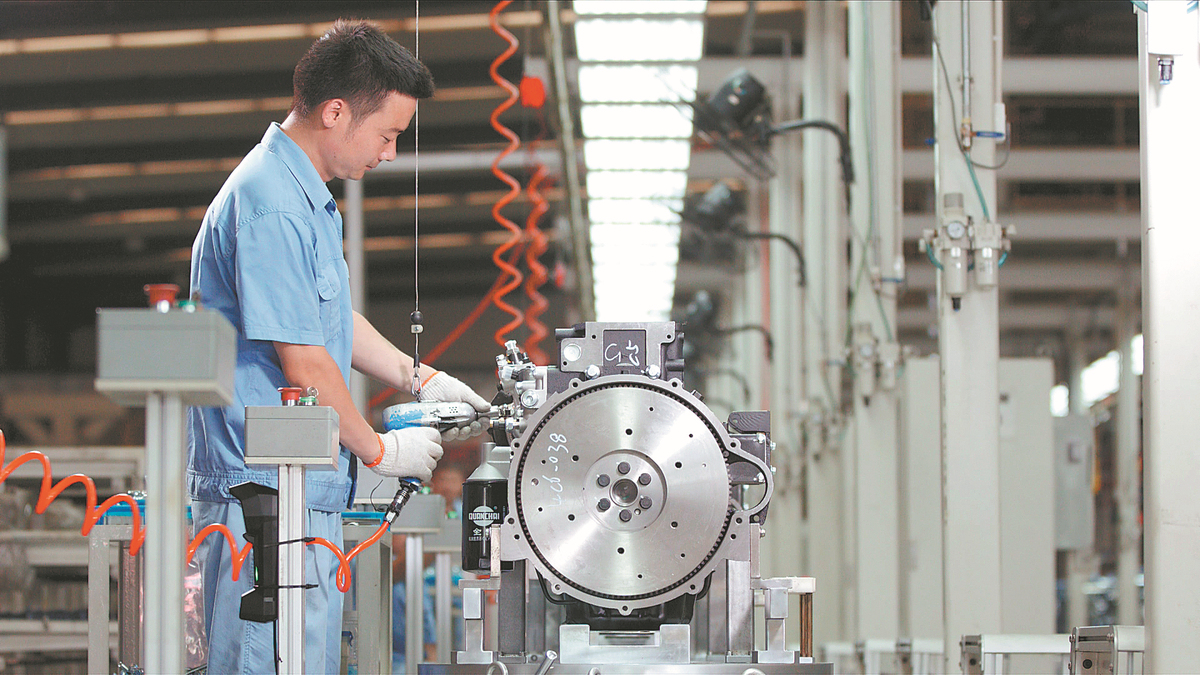

An employee works on the production line of QuanChai Group Co, a Chuzhou, Anhui province-based company. CHINA DAILY

QuanChai Group Co, a Chuzhou, Anhui province-based company known for its rugged internal combustion engines, is finding new life through digital transformation and smart manufacturing.

This shift is key to keeping the 76-year-old company "not just alive, but ahead" in China's fast-evolving manufacturing landscape, said Xu Yuliang, member of the board of QuanChai.

The company, listed on the Shanghai Stock Exchange since 1998, is leveraging China's industrial internet push to revamp everything from its production lines to financial management systems.

The transformation is paying off. In the first quarter of this year, the company's total engine sales rose 15 percent year-on-year, with overseas exports surging 50 percent, putting it firmly among the top three domestic players.

The company's core business remains diesel and internal combustion engines used in trucks, tractors and generators. But in recent years, it has also expanded into hydrogen fuel cells and clean-energy powertrains.

The pivot began during China's 13th Five-Year Plan (2016-20), when the company underwent a full digital overhaul. "This wasn't patchwork," said Xu. "We rebuilt our entire tech, production, management and service chains with digital systems."

That effort included national-level smart factory pilots, integration of ERP and MES systems, and the construction of a proprietary industrial internet platform built around 5G, IoT, edge computing and AI-powered analytics.

According to Xu, the transformation happened in two major stages. First came the "foundation work": integrating data systems across design, production and quality control. "We used to have data silos. Now, a design drawing connects directly to the workshop floor," he said.

During the current 14th Five-Year Plan (2021-25), the company built three key platforms: a digital workshop brain that allows full real-time control over equipment, logistics and quality — all from a smartphone; a quality traceability system that tracks every component from sourcing to after-sales; and a shared financial platform that automates internal audits and reduces risk.

With such efforts, the company said that its research and development cycle time dropped by 30 percent, production efficiency jumped 35 percent and inventory turnover improved by 18 percent.

The company's industrial internet platform now integrates over 850 upstream and downstream suppliers, offering a replicable digital model for China's manufacturing sector.

Looking ahead, the company is betting on industrial large models, such as DeepSeek, to accelerate its evolution.

"Imagine a quality knowledge base that learns from every past fault, or a supply chain that adjusts itself in real time," Xu said. "We're not just building engines anymore. We're offering smart, service-based manufacturing solutions."

The company's roadmap includes mass production of electric drive axles, and expanded applications of hydrogen power. Its engines, which meet global certifications, are already sold across Southeast Asia, Africa, South America and beyond, with cumulative global sales topping 10 million units.

As Xu put it: "The engine may be old, but the brain behind the company is getting smarter every day."